- About the Company

TATRA today

- Company profile

- ET-link

- Company bodies and Organisation Chart

- Quality Management

- TATRA METALURGIE a.s.

- Sponsorship

History of TATRA

Companies of CSG Defence will exhibit at IDEX 2025 in Abu Dhabi together with partners

The traditional IDEX trade fair, one of the world's largest exhibitions of defense technologies and equipment, will take place in the United Arab Emirates (UAE) from February 17 to 21. The companies of the CSG Defence division will present their products and services to experts and the public, together with the local partner, Resource Industries. With an area of 1,500 m2, CSG Defence will have the largest exhibition in the history of CSG group companies' participation in the IDEX trade fair and also the largest Czech exhibition area ever.

- Why TATRA

- Trucks

TRUCKS BY INDUSTRY SEGMENT

PRODUCT CATALOG

- Your TATRA partner

After-sales Services

Customer Centre

Original spare parts

Other

Dealer and Service Network

With the exception of Antarctica, you will find TATRA on every continent. We offer the largest network in Europe.

- Spare parts

- Contact

- Career

TATRA vehicle design

- Developed for heavy off-road conditions

- High passability through terrain

- High levels of driving comfort

- High speeds over difficult terrain

- High levels of vehicle stability in turns and on slopes

- Minimum maintenance requirements and minimum possibility of drivetrain damage

- High chassis rigidity with the central load-carrying tube

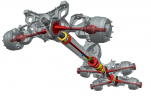

This is a unique chassis concept which originated in the 1920s and has not yet been rivalled. The main principle is the use of a central load-carrying tube and axles with independently suspended swinging half-axles bolted together into a single unit.

Over the years, this “TATRA vehicle concept” has been developed in order to gain the existing original solution which gives TATRA vehicles their unique performance when operating in the most difficult off-road conditions.

Central load-carrying tube

- High torsion and bending rigidity protects superstructures from transmitted loads.

- The modular system enables the assembly of 2-, 3-, 4-, 5- and multi-axle vehicles with the optional all-wheel drive.

- The drivetrain shafts are situated in the central tube and are thus protected against external effects. This allows us to offer high durability and low maintenance costs.

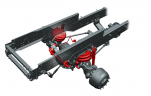

Axles

TATRA axles are, in their basic version, always driven and equipped with locks. A pair of driven crown wheels (one per half-axle) and a pair of pinions transmitting torque from the diferential are placed in the axle housing. The differential is placed outside the axle in the central load-carrying tube, and unlike classic axle solutions with a bevel differential, it is a so-called crown or cylinder-type differential. The inner space of the housing is adapted for the swinging motion of the half-axles. The axles are fitted with pneumatic drum brakes equipped with Perrot wedge spacers, and where required by legislation, also with ABS installation sensors.

Suspension

|

model |

Front axle suspension |

Rear axles |

|---|---|---|

|

TATRA PHOENIX Euro 3 – 6

|

Air bellows 8 – 10 tons per axle |

Air-filled rubber suspension belows + coil spring 11,5 tons per axle Bellows + leaf springs 13 – 16 tons per axle Leaf springs 11,5 tons per axle

|

|

TATRA FORCE (T815-7) Optional level control if the vehicle has air bellows only |

Air bellows 8 – 10 tons per axle |

Air bellows 9 tons per axle Air bellows + leaf springs 13 – 16 tons per axle |

|

TATRA TERRA (T815-2) |

Torsion bars or leaf springs 8 tons per axle |

Air bellows + leaf springs 13 – 16 tons per axle |

Mechanical suspension with load-bearing capacity of up to 8 t per axle using:

- torsion rods for versions with a single steered front axle (4x4 and 6x6);

- leaf springs for versions with two steered axles (8x8, 10x10 or 12x12).

Air suspension with load-bearing capacity of 9 t per axle and the possibility to adjust ground clearance; This type of suspension is primarily intended and developed for T 815-7 range vehicles and its utilisation provides completely different driving characteristics.

All types of suspension are equipped with telescopic shock absorbers and, in some versions, also with torsion bars.